The Nutrient Film Technique (NFT) system is highly adaptable and can be scaled to fit various production sizes. This ranges from small home setups to large commercial operations.

The key to success with NFT hydroponics lies in regular monitoring and maintenance of the system. This includes checking the nutrient solution’s pH and electrical conductivity (EC), ensuring the pump and irrigation system are functioning correctly, and inspecting plants for health and growth progress.

By keeping a close eye on these aspects, you can grow healthy plants and achieve high-quality, marketable crops. But how exactly do you maintain one? Let’s find out.

How to Set Up an NFT System

To set up a Nutrient Film Technique (NFT) hydroponic system, you’ll need the following components:

- Reservoir – A tank to hold the nutrient-enriched water solution.

- Channels – Troughs or trays that will carry the nutrient solution and in which the plants will be placed. These should be shallow and slightly angled to ensure a constant flow of nutrients to the roots.

- Irrigation Lines and Emitters – To distribute the nutrient solution from the reservoir to each channel at a controlled rate.

- Drain Line – To collect the unused nutrient solution from the channels and return it to the reservoir for recirculation.

- Pump – To circulate the nutrient solution from the reservoir through the channels and back.

The space required for an NFT system depends on the size of your setup and the types of crops you plan to grow. A typical table-top NFT system might include six 4-foot-long channels and occupy an area of about 55 inches by 55 inches, with a height of around 31 inches, accommodating approximately 36 plants.

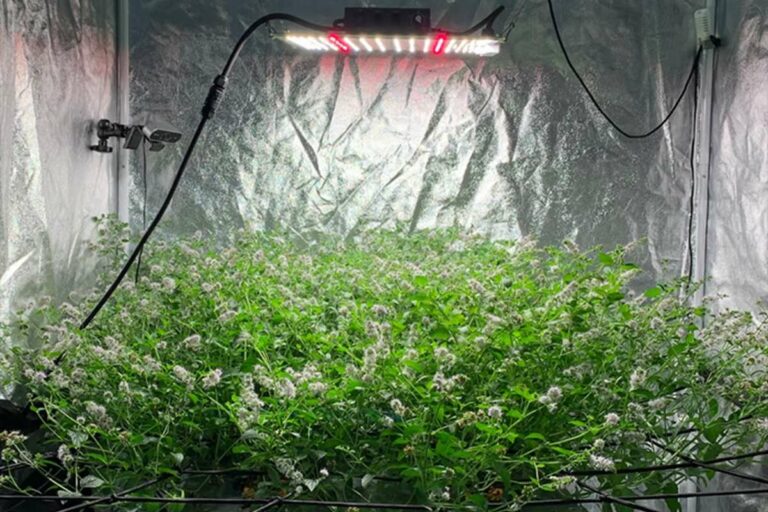

For indoor hydroponics lighting, you should aim for uniform light distribution at the plant level. Depending on your setup and whether it’s in a greenhouse, you might still need supplemental lighting.

Options include High-Intensity Discharge (HID) lamps, fluorescent lights, and Light Emitting Diodes (LEDs).

Just make sure that when selecting lighting, you consider both the initial cost and the long-term energy efficiency of the lighting system.

Tips for Maintaining an NFT System

Hydroponics systems in general require a lot of maintenance, and they might even require daily monitoring depending on the system you’re using.

For an NFT hydroponic system, make sure to adhere to the following regular tasks to ensure effective maintenance:

- Ensure pumps, growing channels, drain lines, and feeding tubes are functioning correctly. Wilted plants can signal a malfunction or plant health issues.

- Regularly check both the foliage and roots for signs of disease, pests, nutrient deficiencies, mildew, or root rot. Early detection is key to managing potential problems.

- Twice a week, verify the level of the nutrient solution in the reservoir. Losses can occur due to plant uptake, evaporation, or leaks. Prevent the reservoir from running too low to avoid pump damage and ensure it’s kept at full capacity.

- Maintain cleanliness in the growing area by swiftly removing plant debris and diseased plants to prevent the spread of pathogens.

- Weekly tests of the water source for pH and electrical conductivity (EC) are crucial. Perform additional tests when adding water to the reservoir, especially after topping off due to evaporation, to maintain the desired water quality.

- After each crop cycle, change the nutrient solution in the reservoir to ensure optimal plant growth. If growth appears slow, consider more frequent changes.

Implementing these maintenance practices will help sustain a healthy NFT hydroponic system, promoting vigorous plant growth and minimizing issues related to pests, diseases, and system malfunctions.

Water Management

Before preparing your nutrient solution for an NFT (Nutrient Film Technique) system, it’s crucial to understand the quality of your water source.

We would recommend that you use municipal water due to its regulated quality. However, testing your source water before setting up your NFT system is essential to identify any potential issues.

Apart from that, knowing the baseline pH (acidity) and EC (electrical conductivity) of your source water is equally as important. This information helps in determining the adjustments needed for your nutrient solution to achieve optimal pH levels for plant growth.

Be cautious of using softened water, as it may introduce excess salts, while hard water might contain high levels of calcium and magnesium. These elements should be monitored and adjusted as needed in your NFT system’s water management practices.

Electrical Conductivity (EC) and Its Importance

EC measures the concentration of dissolved salts (nutrients) in your solution, providing a gauge of the nutrient solution’s strength.

Adding nutrients increases EC while plant uptake decreases it. High EC levels can hinder plant water uptake, leading to wilting, stress, and stunted growth.

That said, you have to keep in mind that EC requirements vary with plant growth stages; younger plants might tolerate higher EC levels, but as plants mature, it’s often necessary to lower EC to prevent stress and maintain plant health.

While EC gives an overall measure of nutrient concentration, it doesn’t specify individual nutrient levels or the presence of micronutrients, so it’s part of a broader nutrient management strategy.

Understanding and managing these aspects of your water source and nutrient solution is fundamental to the success of your NFT hydroponic system.

Fertilizer Management

When selecting a hydroponic fertilizer, consider the form that best suits your needs – liquid or granular. Each has its advantages and considerations.

Liquid fertilizers are easy to measure and mix as they rely on volume measurements. They quickly and evenly disperse in the reservoir water, ensuring immediate nutrient availability to plants. However, containers can be heavy and more challenging to handle, and they may have a shorter shelf life compared to granular fertilizers.

Meanwhile, granular fertilizers are lighter in weight and often more cost-effective, allowing them to have a longer storage life without degradation. However, they require accurate weight measurements for mixing which can be slightly more complex.

Regardless of the type, you want to make sure that the fertilizer is suitable for your specific crops and hydroponic system. Properly mixing and dissolving your chosen fertilizer is crucial for the health and productivity of your hydroponic garden.

Managing Pests in Your Hydroponics System

In order to effectively scout for pests in your hydroponic system, make sure to follow these steps:

- Examine the underside of leaves and the base of plants closely, as these are common hiding spots for pests. Also, check the surface of your growing medium, whether it’s rock wool, clay pebbles, or another material, for any signs of insect activity.

- Place yellow sticky cards on or near your NFT (Nutrient Film Technique) tables to trap flying insects. These cards should be used once per table and checked weekly to monitor for pests. Make sure to replace the cards each week to ensure they remain effective.

- Small pests can be hard to identify with the naked eye. Use a magnifying glass or a loupe to get a closer look. A 30X magnification loupe is often sufficient for identifying common pests.

- For a comprehensive view of pest presence, scout about 25% of your plants regularly. This approach gives you a representative sample to gauge the overall health of your crop and the extent of any pest issues.

Common pests in hydroponic systems include aphids, mites, thrips, whiteflies, and shoreflies. Establishing a routine for regular pest scouting will enable you to detect infestations early and manage them more effectively before they can cause significant damage to your plants.

Tips for Cleaning Your NFT System

Cleaning and sanitizing your hydroponic system between growing cycles or when changing crops is crucial for maintaining a healthy growing environment and preventing disease.

Here’s how you can properly clean your NFT system, particularly the reservoir, trays, and pumps:

Reservoir and Trays Cleaning

Begin by spraying down the reservoir and trays with water to remove any loose plant debris.

After that, use a mild dish soap and warm water to scrub all surfaces and components of the system. Be thorough to ensure all residues are removed. Rinse everything well with clean water to remove soap residue.

Mix 1 tablespoon of unscented bleach (5.25 – 6% sodium hypochlorite) with 1 gallon of water to create a 150-200 ppm solution. Add this solution to the reservoir and circulate it through the system for up to 3 hours.

Afterward, partially fill the reservoir with clean municipal water and let it run through the system for 2-3 hours to ensure all bleach is removed.

You can also use a hydrogen peroxide-based sanitizer that is safe for food contact surfaces, such as ZeroTol 2.0 or Sanidate 5.0. These products are effective for sanitizing and are OMRI-listed. Just make sure to follow the manufacturer’s instructions regarding dosage, personal protective equipment (PPE), contact time, and flushing procedures.

Pump Cleaning

To remove any debris, spray the pump with water to remove any plant matter or algae buildup. Clean the exterior surfaces of the pump with dish soap and a brush to ensure all dirt and residues are removed.

Rinse off the soap thoroughly, then place the pump back into the reservoir to be part of the sanitizing process with the chosen sanitizer.

By following these steps, you can help keep your hydroponic system clean and minimize the risk of pathogens affecting your crops.

Always ensure that any cleaning and sanitizing agents used are thoroughly rinsed from the system to prevent harm to your plants in the next growing cycle.

+ There are no comments

Add yours